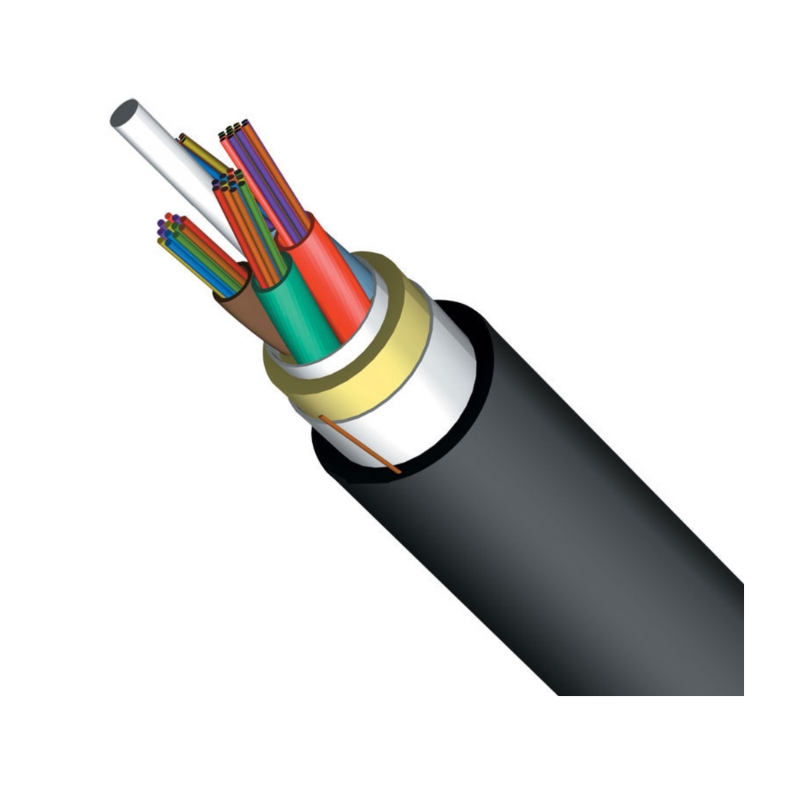

ADSS Fiber Optic Cable 400 SPAN B1.3 PE

Price: Rs 198000

Fiber Specifications

- Material: Quartz glass (Silicon Dioxide)

- Structure:

- Core: 9 μm (high refractive index)

- Cladding: 125 μm (low refractive index)

- Coating: 245 μm (protective resin)

|

Parameter |

Requirement |

Standard (if applicable) |

|

Core non-circularity |

≤ 6% |

ITU-T G.652 |

|

Cladding diameter |

125.0 ± 0.7 μm |

- |

|

Core/Cladding concentricity |

≤ 0.6 μm |

- |

|

Cladding non-circularity |

≤ 1.0% |

- |

|

Coating diameter |

245 ± 10 μm |

- |

|

Cladding/Coating concentricity |

≤ 12 μm |

- |

|

Attenuation coefficient |

1310 nm: ≤ 0.35 dB/km 1550 nm: ≤ 0.21 dB/km |

- |

|

Zero dispersion slope |

≤ 0.092 ps/(nm²·km) |

- |

|

Zero dispersion wavelength |

1300–1324 nm |

- |

|

Polarization dispersion |

≤ 0.20 ps/√km |

- |

|

Mode field diameter (1310 nm) |

9.0 ± 0.4 μm |

- |

|

Cut-off wavelength |

1170–1330 nm |

- |

|

Chromatic dispersion |

1288–1339 nm: ≤ 3.4 ps/(nm·km) 1550 nm: ≤ 18 ps/(nm·km) 1625 nm: ≤ 22 ps/(nm·km) |

|

Cable Parameters

|

Parameter |

Value |

|

Fibers per loose tube |

6 |

|

Number of tubes |

2 |

|

Inner sheath thickness |

1.0 mm |

|

Outer sheath thickness |

1.7 mm |

|

Aramid area |

2.8 mm² |

|

Cable diameter |

12.5 mm (±5%) |

|

Cable cross-section |

106 mm² |

|

Cable weight |

105 kg/km (±10%) |

4. Mechanical & Environmental Performance

- Key Parameters:

- RTS (Rated Tensile Strength): 4800 N

- MAT (Maximum Allowable Tension): 1900 N

- Static bending radius: ≥ 174 mm

- Dynamic bending radius: ≥ 290 mm

- Operating temperature: -40°C to +70°C

- Installation temperature: -10°C to +40°C

5. Test Requirements

|

Test Type |

Standard |

Key Criteria |

|

Tensile Test |

IEC 60794-1-21-E1 |

- RTS: No break at 100% RTS. - UOS (60% RTS): Fiber strain < 0.35%, no added attenuation. - MAT (40% RTS): Strain < 0.05%. |

|

Crush Test |

IEC 60794-1-21-E3 |

≤ 0.1 dB attenuation @1550 nm under 2200 N; no residual attenuation. |

|

Impact Test |

IEC 60794-1-21-E4 |

450g weight, 1m height, 5 impacts. No sheath cracks or residual attenuation. |

|

Repeated Bending |

IEC 60794-1-21-E6 |

30 bends under 150 N load. No cracks/residual attenuation. |

|

Torsion Test |

IEC 60794-1-21-E7 |

±180° twist, 10 cycles. No added attenuation or sheath damage. |

|

Temperature Cycling |

IEC 60794-1-22-F1 |

-40°C to +65°C, 2 cycles. Attenuation < 0.05 dB/km @1550 nm. |

|

Water Penetration |

IEC 60794-1-22-F7 |

1m head for 1 hour. No leakage. |